SPECIFICATIONS

ENGINE:

Honda GX270

DETAILS:

Length: 66″

Width: 20.75″

Height: 36″

Tilling Width: 18″

Weight: 460 lbs.

Hydraulic Reservoir: 7.8 gallons

Ground Drive Forward: 78 ft/min

Ground Drive Reverse: 78 ft/min

Handlebar Pivot Angle: Up to 20˚

Honda GX270

DETAILS:

Length: 66″

Width: 20.75″

Height: 36″

Tilling Width: 18″

Weight: 460 lbs.

Hydraulic Reservoir: 7.8 gallons

Ground Drive Forward: 78 ft/min

Ground Drive Reverse: 78 ft/min

Handlebar Pivot Angle: Up to 20˚

DESIGN

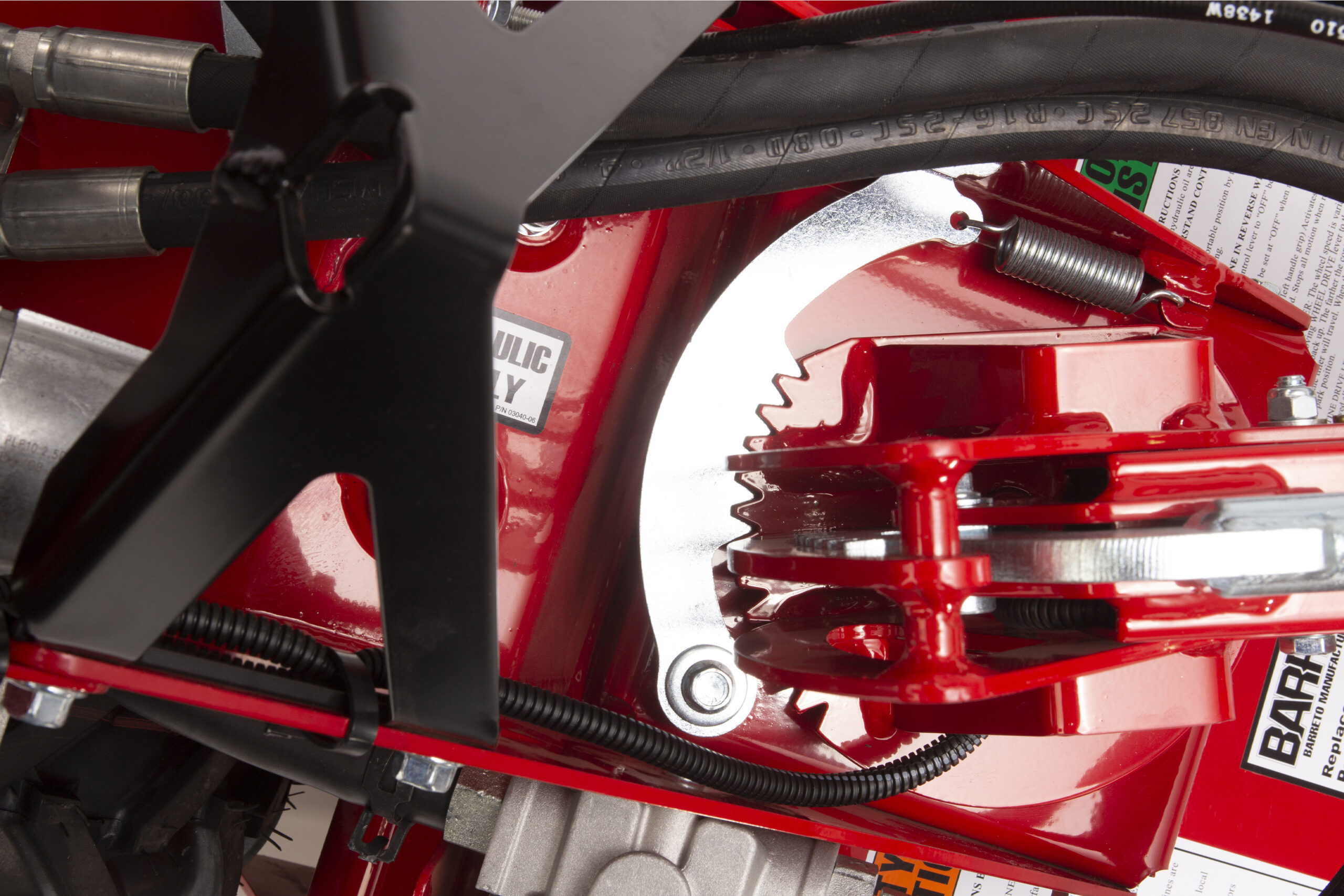

All hydraulic means easy maintenance, no downtime, and the most efficient use of your horsepower to get the job done. Till effectively in small spaces by choosing an 18″ tilling width of the 918 rear tine tiller. The open design provides easy access to the hydraulics when maintaining or repairing. The unique swivel handlebar featured on this compact unit means you can walk alongside your tiller rather than in your freshly tilled earth. The heavy design means your tiller works for you instead of tossing you around. Counter-rotating tines break up the most difficult soil, clay, or sod. Wheels and tines work independently of each other to allow your tilling travel speed to be adjusted to the soil conditions.

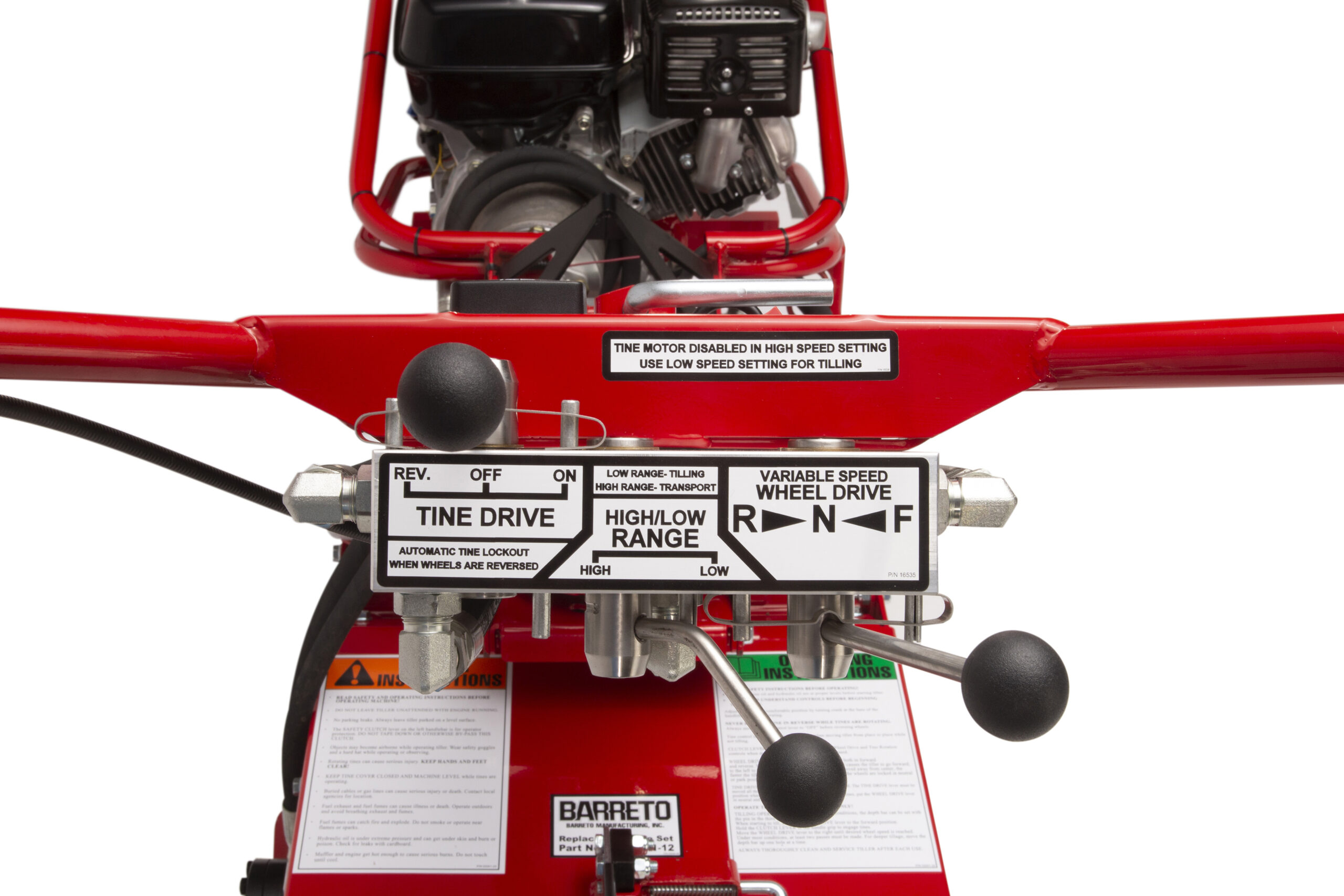

CONTROLS

The operator-friendly controls couldn’t be easier: one handle to set the tine drive and one to adjust the wheel drive. Engage the clutch lever, use the variable speed drive to adjust the ground speed, and engage the tines when you are ready to till. If you need to stop for a moment, drop the clutch and the tines and wheels will stop, leaving your engine running and ready to pick up where you left off.

ROI

With no belts, chains, or gears to mess with, maintenance on the 918 rear tine tiller is minimal. A simplified control valve at the handlebar further reduces moving parts. The hydraulic motor is recessed into the outside of the frame for easy accessibility and removal. Ball bearing support on each end of the tine shaft allows the motor to be removed for service by simply removing two bolts. A tiller that is down produces no revenue: by choosing hydraulics, you’ll increase utilization and minimize maintenance costs, improving your bottom line.